Not known Factual Statements About Steel Road Plates

Not known Factual Statements About Steel Road Plates

Blog Article

The Of Steel Road Plates

Steel layers are give a great, momentary solution for covering hazardous holes on a construction site. These heavy-duty, robust plates permit roads to return to solution so that construction can proceed. Here we discover the design information and finest practice installation recommendations. These plates can be utilized to guarantee that roadways can still be used whilst other stages of job proceed.

They provide an optimal concession for maintaining lanes, whilst work proceeds over night and at weekend breaks. They are frequently seen when excavations have actually started as an onset of building and construction or repair work jobs. These plates are made to stand up to sturdy usage on active roads. They feature an akti-skid finishing and are readily available in a variety of colour finishes - Steel road plates.

The weights start from about 300kg and standard road plates have a thickness of either inch or inch. We can also offer customised sizes. The key features of the item are as adheres to: Holes to enable safe accessory to lifting plants. The capability to be bolted to the road.

8 Easy Facts About Steel Road Plates Shown

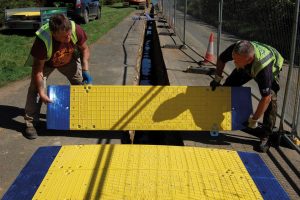

Hinged versions for fast accessibility to the excavation or regular accessibility, e.g. driveways. Composite plates, which can accommodate various sizes of trench. Skid-resistance for enhanced lorry, pedestrian and site worker security. Steel roadway plates can be mounted relatively swiftly, but they are hefty. Because of this, they need to be set up using a forklift or crane.

Check for variation by website traffic filling from the outset plates ought to constantly withstand variation. Check that the plates do not provide a hazard to any type of type of roadway customer and can be used by all road customers and vehicle types, consisting of pedestrians, bikers and motorcyclists. Produce a normal assessment and upkeep to guarantee that efficiency stays secure and optimum.

Take care of the plates properly in all times. Mechanical training makes certain that the plates are installed accurately and safely. The appropriate plates should appropriate for the desired function Take into consideration proper safety zones, particularly when preparing installment. The weight of home plates can cause swinging in the building area or across adjoining carriageways/ footways.

If a ramp is created by the roadway layers, after that advising indicators for pedestrian and road customers are called for. Constantly a conduct full website survey, and take the expert suggestions of an architectural engineer.

Not known Details About Steel Road Plates

In order to boost security, there are a variety of criteria and advice industry papers guiding their use in building job zones. This article supplies some highlights that might be valuable in starting your examination. If you call for additional details, please get in touch with our specialist straight. Steel plates have to be taken care of in position to prevent movement.

Some Known Details About Steel Road Plates

In enhancement to being securely in contact with the pavement, they need to be either pinned, recessed right into the sidewalk, or safeguarded with asphalt wedges around the border. Pinning right into the pavement entails driving pins right into the sidewalks along the edges of the steel plates to prevent movement. Recessing entails reducing out the location where the steel plate will be positioned.

This causes the steel plate being flush with the pavement. In addition, when several steel plates are used and butt up to each various other, they must be welded together at the longitudinal joints. Steel plates can be extremely slippery, specifically when they are damp, unless they have an anti-skid layer applied.

Covering steel plates with a product that increases rubbing assists motorcyclists and bicyclists keep control, particularly in wet weather condition. Problems which minimize pavement rubbing in work zones are of certain issue to motorcyclists and bikes. A typical risk in steel plate installations takes place when the customer fails to create appropriately tapered ramps from the street to the sides of the steel plate( s).

3 Simple Techniques For Steel Road Plates

It positions a significant risk to motorcyclists and bicyclists who can quickly shed control when they contact the abrupt/steep tapered ramp and the steel plate. Effectively conical ramps enable customers to securely cross over the steel plates. Tapers for steel plates are usually built of asphalt. The taper sizes differ from One state to another and generally range from 20 to 1 to 120 to 1 (Steel road plates).

Department of Transportation's Federal Freeway Management (FHWA) needs that transverse sidewalk joints, which cause a bump, have to read more be tapered at 60 to 1 (5 feet straight for every 1 inch of vertical altitude distinction). Select the correct size. Ensure appropriate overlap. Usually, steel plates need to prolong a minimum of one foot past the pavement opening onto firm ground.

6 Simple Techniques For Steel Road Plates

Welding is made use of when more than one steel plate is made use of and they butt up to each other. Plates should be countersunk when required due to irregular highways.

His that site background consists of the construction, evaluation, learn more.

These sturdy steel plates play an essential role in boosting construction security, offering temporary roadways, and ensuring smooth operations on numerous task sites. As a construction tools provider, their value can not be overstated.

Report this page